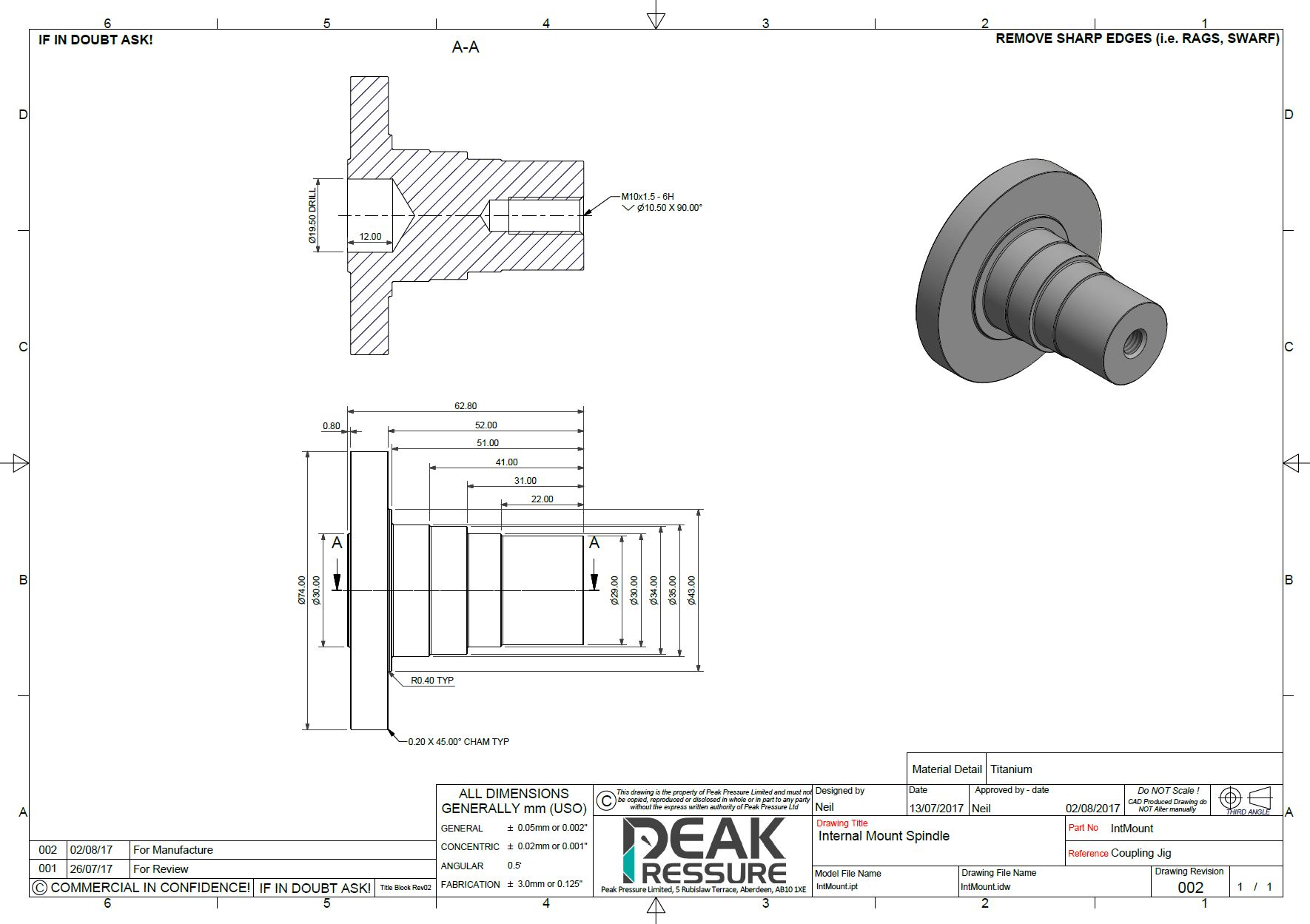

Drafting

Drafting to customer requirements, and to international standards. Proficient in the use of Autodesk Inventor and Solidworks.

Engineering Support Services

Professional Engineering Resources To Top Up Capacity, Or Bridge Skills Shortages.

I provide a range of engineering services on site, or from an office in Aberdeenshire.

For further information please get in touch.

Drafting to customer requirements, and to international standards. Proficient in the use of Autodesk Inventor and Solidworks.

I understand the challenges that can come with a requirement for representative testing, and posess the experience and expertise to develop and build systems for a wide range of testing.

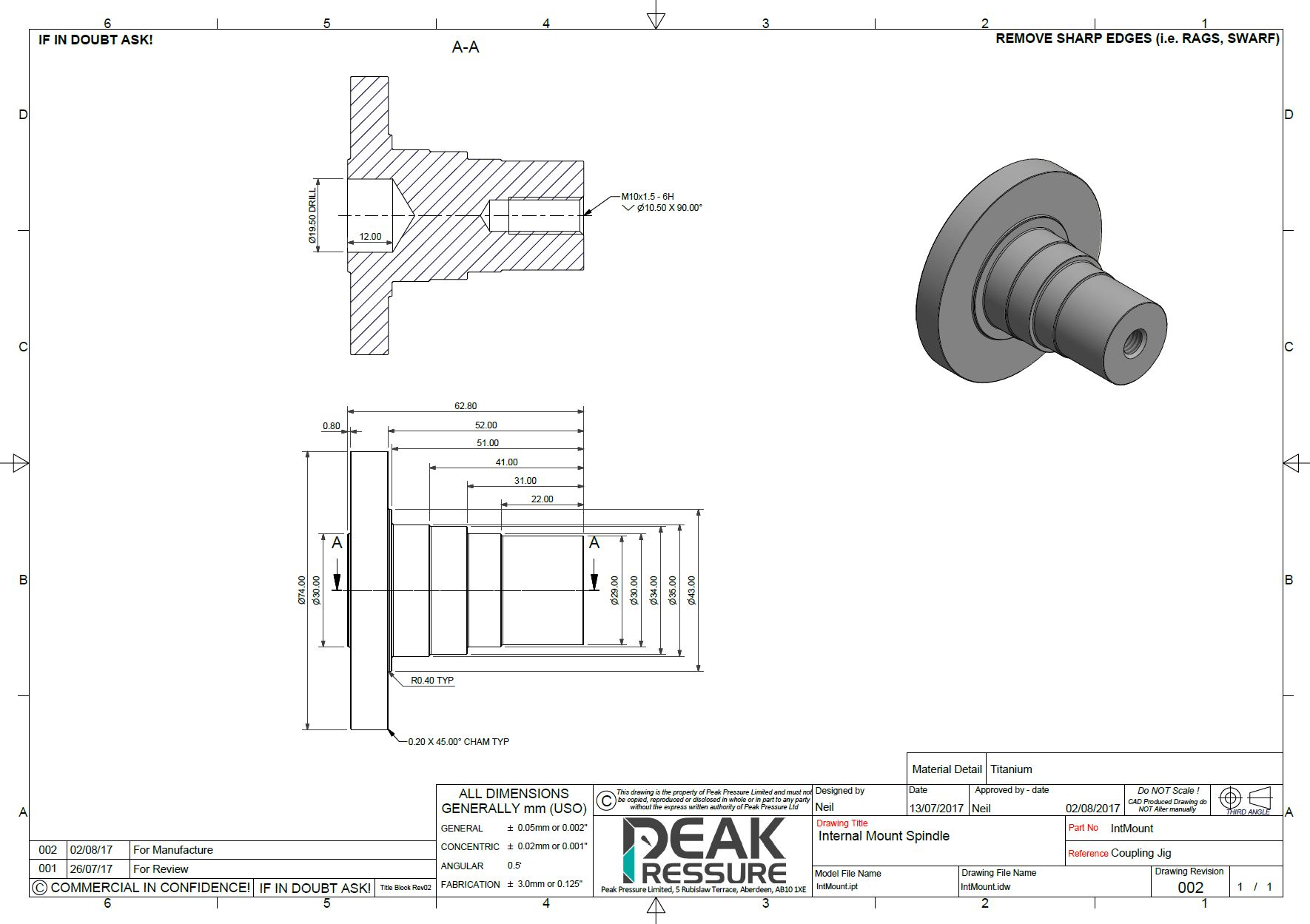

I have over 15 years of experience working with a variety of pressure containing equipment ranging from miniaturised precision pressure control devices you can pick up and hold in 1 hand, to large complex systems occupying a whole hangar.

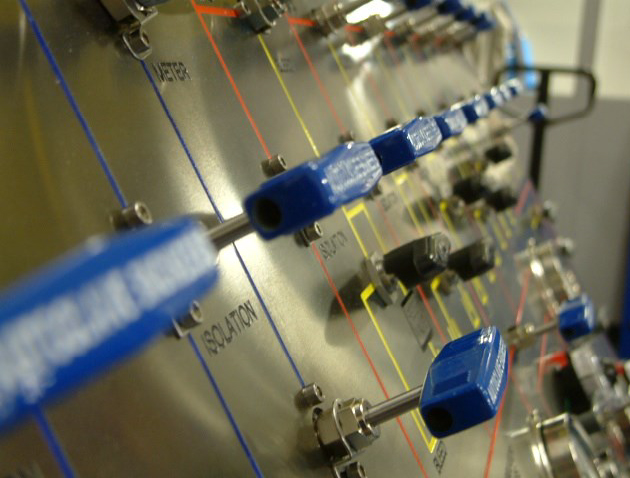

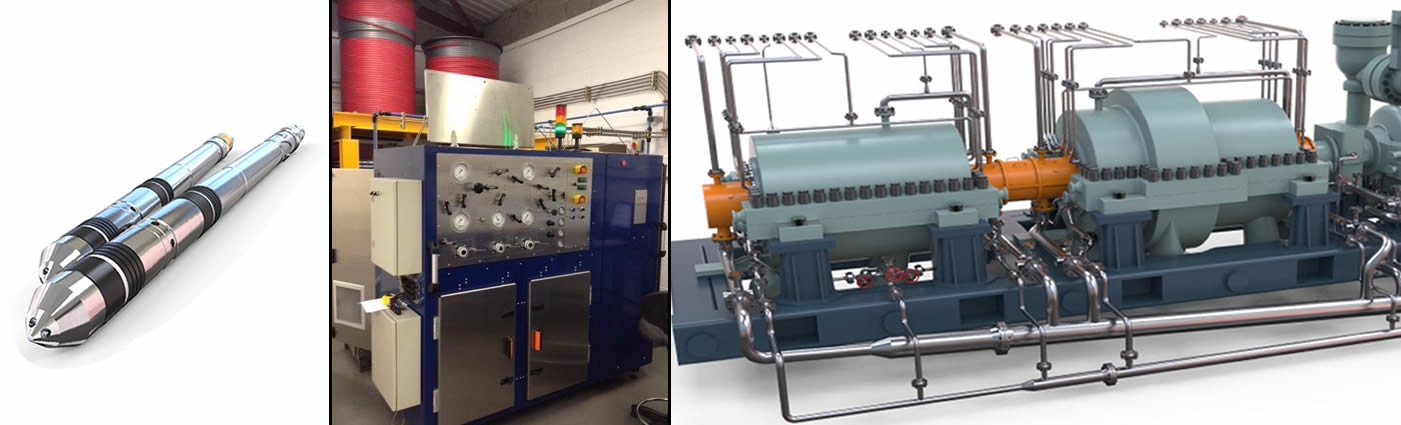

One of my key areas of expertise is with down hole completion equipment for the oil and gas industry. I functioned as the senior product engineer of todays leading range of down hole chemical injection equipment available on the market today. The challenges overcome with this experience provided valuable opportunities to develop precision skills and critical thinking which are carried forward into Peak Pressure today. Still recognised as a technical expert on the subject, I have contributed to the construction of a new API standard created to improve knowledge and reliability in this market.

Another example area of my expertise is with gas compressor related systems. These large machines must be reliable, which depends on key components such as dry gas seals being protected. I have built experience developing specific technology and incorporating it into systems to carefully and intelligently control the conditions these pieces of equipment are exposed to. Harnessing the capabilities of high technology software tools to simulate chemistry changes within gas, and analyse transient magnetism forces has propelled my ability to understand the challenges in this environment.

All equipment must undergo testing to ensure it operates as required. My approach has been to avoid costly outsourcing of development and qualification testing by developing in house test facilities to meet the requirements of specific products. This experience allows me to resolve testing requirements whether the solution is a basic pump unit, or a sophisticated test system enclosed in a bespoke cabinet.